Environmental Recycling

Going green is no longer a fringe activity for brands.

We see more and more global brands making the significant changes necessary to be more sustainable and to work toward green.

rPET Felt Product’s Low Carbon Footprints

All the felt products in VicRound Acoustic Collection are made with GRS certificated rPET.

You might think plastic is not a typical sustainable material, but considering the manufacturing process, carbon emissions and recyclability, rPET felt products do a really good job in sustainability.

We see more and more global brands making the significant changes necessary to be more sustainable and to work toward green.

rPET Felt Product’s Low Carbon Footprints

All the felt products in VicRound Acoustic Collection are made with GRS certificated rPET.

You might think plastic is not a typical sustainable material, but considering the manufacturing process, carbon emissions and recyclability, rPET felt products do a really good job in sustainability.

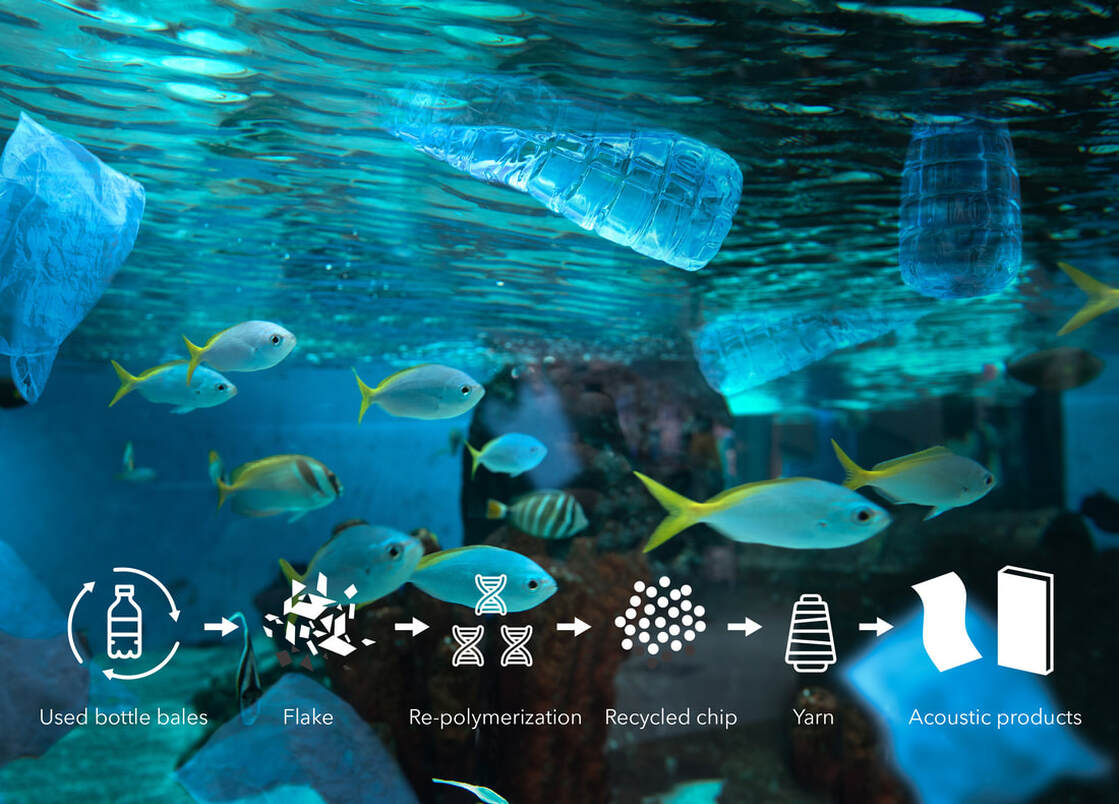

From recycled to recycle

ACOUSTIC CHAMBER INSTALLATION

Product development with a reduced carbon footprint

In the textile product line, we have also done a series of "deodorizing" developments for gaming mouse pads. The goal is to solve a long-standing problem - the smell of plastic.

Item 1: Made of recycled materials, the surface is made of 100% rPET yarn, and the bottom material is made of recycled material foaming. The carbon footprint information is being completed in accordance with the order of product development completion. It is expected to be fully completed in 2023Q3.

Item 2: Customized products that solve the need for e-sports players to move their wrists comfortably due to long hours of gaming. Not only can it "deodorize", but also can be customized or color-designed gaming mouse pads according to various brands.

Item 1: Made of recycled materials, the surface is made of 100% rPET yarn, and the bottom material is made of recycled material foaming. The carbon footprint information is being completed in accordance with the order of product development completion. It is expected to be fully completed in 2023Q3.

Item 2: Customized products that solve the need for e-sports players to move their wrists comfortably due to long hours of gaming. Not only can it "deodorize", but also can be customized or color-designed gaming mouse pads according to various brands.

FAQ

Q1 What is the difference between sponge and rPET?

Material origin: Sponge is usually made of a variety of different materials, such as polyurethane foam, natural rubber, or other synthetic materials. rPET is made from recycled polyester (Recycled Polyethylene Terephthalate), which is obtained by recycling and reprocessing waste polyester materials such as plastic bottles. Sustainability: rPET is a sustainable material as it is made from recycled plastic, helping to reduce the amount of waste and the need for new raw materials. In contrast, sponges are often made from new raw materials, which have a greater environmental impact.

Physical properties: Sponge generally has soft, elastic and hygroscopic properties, and is suitable for various applications, such as seat cushions, sponge pads, etc. While rPET is usually used to make fibers, textiles and plastic products, it is wear-resistant, durable and lightweight.

Application fields: Due to their different properties, sponge and rPET have different uses in different application fields. Sponge is widely used in furniture, mattresses, car seats and other products that require comfort. rPET is commonly used to make clothing, bags, rugs, household items and more. Overall, sponge and rPET are two distinct materials that differ significantly in terms of material origin, sustainability, physical properties, and application areas. Choosing a material that is suitable for a specific need and is environmentally friendly depends on the specific application scenario and priorities.

Q2 What materials are used for 100% recycling?

We use recycled polyester (Recycled Polyethylene Terephthalate) to make related textile products. It is recycled and reprocessed waste polyester materials (such as plastic bottles) to make new products. This method is called recycling. It can reduce dependence on natural resources, achieve a 100% recycling rate, reduce consumption of natural resources, and have a positive impact on the environment.

Q3 Are there any world standard specifications for reducing echo and increasing sound absorption?

Yes, ISO 11654 is currently used as the standard specification for noise reduction testing. The NRC number is between 0 and 1. The larger the number, the better the ability to reduce echo. According to the sound experiment of National Cheng Kung University, our sound-absorbing products have reached NRC 0.9.

Material origin: Sponge is usually made of a variety of different materials, such as polyurethane foam, natural rubber, or other synthetic materials. rPET is made from recycled polyester (Recycled Polyethylene Terephthalate), which is obtained by recycling and reprocessing waste polyester materials such as plastic bottles. Sustainability: rPET is a sustainable material as it is made from recycled plastic, helping to reduce the amount of waste and the need for new raw materials. In contrast, sponges are often made from new raw materials, which have a greater environmental impact.

Physical properties: Sponge generally has soft, elastic and hygroscopic properties, and is suitable for various applications, such as seat cushions, sponge pads, etc. While rPET is usually used to make fibers, textiles and plastic products, it is wear-resistant, durable and lightweight.

Application fields: Due to their different properties, sponge and rPET have different uses in different application fields. Sponge is widely used in furniture, mattresses, car seats and other products that require comfort. rPET is commonly used to make clothing, bags, rugs, household items and more. Overall, sponge and rPET are two distinct materials that differ significantly in terms of material origin, sustainability, physical properties, and application areas. Choosing a material that is suitable for a specific need and is environmentally friendly depends on the specific application scenario and priorities.

Q2 What materials are used for 100% recycling?

We use recycled polyester (Recycled Polyethylene Terephthalate) to make related textile products. It is recycled and reprocessed waste polyester materials (such as plastic bottles) to make new products. This method is called recycling. It can reduce dependence on natural resources, achieve a 100% recycling rate, reduce consumption of natural resources, and have a positive impact on the environment.

Q3 Are there any world standard specifications for reducing echo and increasing sound absorption?

Yes, ISO 11654 is currently used as the standard specification for noise reduction testing. The NRC number is between 0 and 1. The larger the number, the better the ability to reduce echo. According to the sound experiment of National Cheng Kung University, our sound-absorbing products have reached NRC 0.9.

|

|

|